Reverse osmosis tubes in a dessalination plant. Image licensed by Stockphoto.com.

Seven-tenth of our planet's surface is covered with water. This abundance masks the fact that water is locally in short supply in many parts of the world. California has been experiencing severe drought, and reservoirs such as Lake Mead are experiencing record lows. As climate change is likely making such droughts more common in the future, countries are looking for alternative supplies of water.

With the world's population continuing to grow, the world's quench for water continues to rise despite efforts to improve water efficiency. Combined with dwindling supplies of freshwater, the search for alternative supplies of water has led to the coming of age of seawater desalination. Technological progress over the last two decades has made desalination an economically feasible proposition, although large-scale use of this technology is not without its own environmental challenges.

At a cost of US$1 billion, San Diego county (not the city) is building a desalination plant in Carlsbad that will supply 190 million litres per day (MLD) to the region. In Israel, several desalination plants are already delivering 1,350 MLD of potable water, and as further plants are being built, this number is expected to rise to 2,075 MLD by 2020. The Sorek desalination plant south of Tel Aviv, completed in 2013, is the largest such plant on the planet with a capacity of 624 MLD. Together, these desalination plants account for four-tenth of Israel's water supply, and by 2020 this share will rise to one-half.

Israel is also leading the way recycling water. Treated muncipal wastewater is used for agriculture irrigation instead of freshwater. Israel also has pioneered other ways to conserve water. Drip irrigation has replaced inefficient spray irrigation. The company that started this technology in 1965 is Israel's Netafim. Within decades, it changed the world of agricultural irrigation. Today, Netafim operates through 37 subsidiaries in 150 countries with 13 factories around the world. Now the new pioneers are the desalination companies. Israel's IDE Technologies is among them, and is involved in budiling the San Diego plant. Among the engineering giants, France's Veolia Environment is the leader, followed by South Korea's Doosan and the Power & Water division of US conglomerate General Electric.

What are the technological choices for desalination?

While there are numerous ways to desalinate seawater, in practice there are only two competing industrial-scale technologies: distillation and reverse osmosis. Distillation is the conventional method for desalination, and it requires heat—plent of it. The most common form is called multi-stage flash (MSF). Distillation can be made more efficient by using waste heat, arranging the distillation in multiple stages with heat exchangers that recover and reuse heat, and by lowering the pressure and achieving boiling at low temperatures. For smaller applications that often use waste heat, a variant of MSF is Multi-Effect Distillation (MED). The main alternative to distillation is reverse osmosis (RO), which uses high levels of pressures and semi-permeable membranes. In recent years, reverse osmosis has become the dominant technology because it is more energy efficient than distillation.

How does a desalination plant work?

A typical reverse osmosis desalination plant operates in several steps, from taking in water to storing and delivering water to the end users.

- Water intake: Pipes extend from the desalination plant far into the ocean. The water that is pumped through these pipes are protected by screens to prevent fish and other sea life, or any debris, from entering the desalination process.

- Pretreatment: After reaching the desalination plant, seawater is filtered to remove sediments as well as micro-organisms (bacteria, viruses). Filtration takes place in several stages. Larger particles (more than 100 micrometer) are removed first, and then ultra-filtration membranes remove tiny particles (larger than 40 nanometers). The resulting solid waste is removed to landfills.

- Desalination process: How the water is desalinated depends on the specific process. The most common method for large-scale plants is reverse osmosis, described below in detail.

- Wastewater discharge: The desalination process generates brine, which is now much more salty than seawater. It can be mixed with wastewater from other sources to reduce its salinity before being discharged back into the sea, ideally far from the original water intake.

- Post-treatment: To make the water safe for drinking, it is either chlorinated, ozonated, or exposed to high levels of ultraviolet radiation to destroy any remaining germs.

How does reverse osmosis work?

Reverse osmosis is a type of filtration process that requires high levels of pressure to force water through a semi-permeable membrane with tiny pores. Water molecules fit through the membrane, but salt molecules do not. Generating the high levels of pressure in the range of 5-10 MegaPascal (MPa) requires significant amounts of energy. The energy efficiency of a desalination plant can be expressed in kilowatthours per cubic meter (kWh/m3). The theoretical limit for desalination is 1 kWh/m3, but state-of-the-art desalination plants that utilize energy recovery achieve about 3.5 kWh/m3. This is a huge improvement over earlier technologies, which often required double or more that energy in the 1970s.

Reverse osmosis membrane systems are typically built as tubes, with several layers of material wound around a central tube in a spiral. Feed solution enters on one end of the tube, and the concentrate on the other. The permeate (desalinated water) spirals inward and exits through the perforated central tube. The layers consists of an outer wrap, a feed channel spacer, the membrane, a permeate collection layer, another membrane, and a feed channel spacer. Thus there is one permeate channel for two feed solution channels.

The most important practical drawback of reverse osmosis is membrane fouling. After some time, the membranes deteriorate and need to be replaced. This makes desalination more costly. Finding ways to prevent or reduce fouling are therefore central in research and developmnt of improve RO systems.

Technological progress is likely to improve the cost-efficiency of reverse osmosis. For example, the Sorek plant in Israel employs larger tubes, 40cm in diameter rather than the usual 20cm tubes. Bigger tubes reduce the need for pipes to connect the tubes, and this reduces cost.

Is forward osmosis an alternative to reverse osmosis?

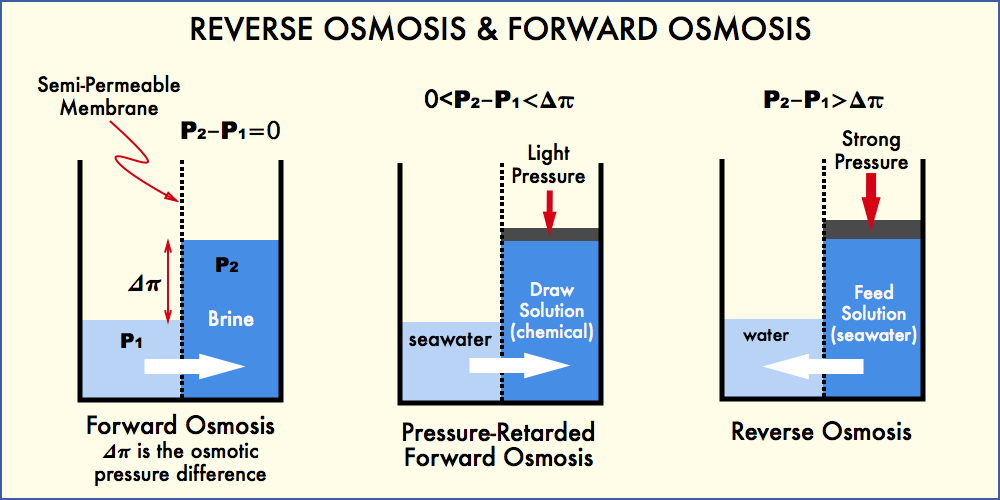

Let us back up for a moment and have a closer look at osmosis. Osmosis occurs when solvent molecules move spontaneously through a semi-permeable membrane towards a region of higher solute concentration, as shown in the left-most part in the diagram below. The osmotic pressure of a solution is proportional to the product of temperature and the molar concentration of the solute particles in the solution. The osmotic pressure differential \(\Delta\pi\) is the minimum pressure that needs to be applied to prevent solvent from crossing through the membrane. If no external pressure is applied and we start with equal amounts of clear water on the left side and seawater on the right side, osmosis will equilibrate the concentration levels of both solutions, and this will result in lowering the column with the originally clear water and lifting of the column with the now-diluted seawater. In that case, the osmotic pressure on both sides of the membrane will be equal, \(P_1=P_2\). Reverse osmosis reverses this natural process, but as described above requires lots of external force, as shown at the very right of the diagram. In that case, the feed solution is put under a lot of pressure so that \(P_2\) is very high and \(P_2-P_1>\Delta\pi\). The induced pressure differential exceeds the natural osmotic pressure differential, and this reverses the osmosis process.

Some companies claim that forward osmosis has benefits over reverse osmosis. Such plants use a technique called "pressure-retarded forward osmosis" (PRO). With PRO, the external pressure is lighter and this consumes less energy. The induced pressure difference \(P_2-P_1\) is now smaller than the osmotic pressure differential \(\Delta\pi\). The basic idea is that seawater is permeating through the membrane into a draw solution that is even saltier than seawater. The Al Khaluf plant in Oman, built by ModernWater, claims to use 30% less energy than conventional RO plants. The middle part of the diagram explains how this works. With forward osmosis, seawater is fed into the system, and a chemical osmosis agent draws freshwater through membranes. The freshwater dilutes the osmotic agent, and a regeneration system removes the pure water and reuses the osmotic agent. Unlike reverse osmosis, which is most often electrically powered, the regeneration process in forward osmosis is often thermally or chemically driven. The non-toxic osmotic agent is a chemical compound, an there is a fair amount of experimentation going on with suitable compounds (inluding calcium chloride and borax). The first step in the process consumes little power, but the regeneration step is more energy-intensive. Some researchers think that the potential of forward osmosis is limited because on a theoretical level FO does not outperform RO in terms of energy consumption (McGovern and Lienhard, Journal of Membrane Science 2014). Besides desalination, forward osmosis has numerous other useful applications, for example in treating contaminated water.

Whatever the relative merits of PRO and RO, there is a lot of research going into finding better, cheaper, and more environmentally friendly desalination methods. Expect to see a fair bit of innovation over the next years.

Does desalination pose environmental challenges?

Desalination plants have an environmental footprint. First, They consume lots of energy. If this energy comes from fossil fuel sources (as is common for desalination plants in the Middle East), there are air and greenhouse gas emissions. Using renewable energy alleviates such issues. The 90 MW of electricity needed to operate the new Victorian Desalination Project near Melbourne, Australia, which opened in December 2012, will soon be complemented by the nearby 63MW Oakland Hills wind farm.

The second challenge is water intake. Screened surface intakes are cheap, but subsurface intakes are better. With a subsurface intake, seawater is drawn in through perforated pipes below the sea floor where the layers of sand and mud act like a filter to sceen out most organisms. Such "seabed filters" are a trade-off. One one hand they are more expensive to build and maintain, but on the other hand they reduce the need to build expensive filtration systems for the pre-treatment stage. Surface intakes are considered harmful because they can draw in fish eggs and other useful organisms that slip through the screens.

The third challenge is the discharge of the brine, which is typically twice as salty as the seawater pumped into the desalination plant. The high salinity of the brine may affect marine life adversely. One way to mitigate the problem is to dilute the brine with other wastewater before discharging it to sea. Dilution is also helped by strong currents. Other types of discharge technologies are in experimental stages.

How expensive is seawater desalination?

Desalinating seawater is becoming increasingly affordable. For comparison, municipal drinking water in the Vancouver area is typically priced around $1 per cubic meter. This cost includes delivery and sewage, however, while the water itself is effectively free. Think of the cost of desalination as the extra cost on top of such a "base fee" for the existing infrastructure. If electricity is priced at 10 cents per kWh, the power cost for desalination comes to about 35 cents per cubic meter. Capital costs and maintenance costs add about the same amount, and desalination comes at a cost of much below $1 per cubic meter. Costs for desalination are expected to fall further, also as rewnewable sources of energy are becoming cheaper. There are several reports that suggest that desalination costs have fallen below 0.60 USD/m3 for large-scale plants.

Desalination technology benefits from economies of scale—larger is cheaper. However, desalination can also be put into very compact systems that can be used in smaller communities, or on cruise ships. When cost considerations are not the main concern, alternative technologies may provide more flexible or compact solutions. For example, Finnish ship outfitter Wärtsilä produces vacuum distillation units that use waste heat from diesel engines to desalinate seawater.

Which are the largest desalination plants in the world?

The table below lists desalination plants with a capcity larger than 100 MLD. This table is still "work in progress"; it may miss some plants and in some cases the technology that is used is not readily identifiable. I will continue updating this table, and if you would like to report errors or omissions, please e-mail me.

| Desalination Plant | Country (Region/City) | Capacity [MLD] |

Year Opened |

Type |

|---|---|---|---|---|

| Gold Coast | Australia (Queensland) | 125 | 2009 | RO |

| Perth | Australia (Western) | 130 | 2006 | RO |

| Kurnell | Australia (New South Wales) | 250 | 2010 | RO |

| Wonthaggi | Australia (Victoria) | 410 | 2012 | RO |

| Cap Djinet | Algeria | 100 | RO | |

| Tlemcen Souk Tleta | Algeria | 200 | RO | |

| Tlemcen Hounaine | Algeria | 200 | RO | |

| Beni Saf | Algeria | 200 | RO | |

| Tenes | Algeria | 200 | RO | |

| Fouka | Algeria | 120 | RO | |

| Skikda | Algeria | 100 | RO | |

| Hamma | Algeria | 200 | 2008 | RO |

| Mostaganem | Algeria | 200 | RO | |

| Magtaa | Algeria | 500 | 2014 | RO |

| Beijing | China (Tianjin) | 200 | RO | |

| Nemmeli | India | 100 | 2013 | RO |

| Ashkelon | Israel | 120 | 2005 | RO |

| Hadera | Israel | 127 | 2009 | RO |

| Sorek | Israel | 410 | 2013 | RO |

| Ashdod | Israel | 100 | 2014 | RO |

| Jeddah | Saudi Arabia (West Coast) | 402 | 1978-94 | MSF/RO |

| Al Shoaibah | Saudi Arabia (West Coast) | 583 | 1989-2002 | MSF |

| Yanbu | Saudi Arabia (West Coast) | 321 | 1981-1999 | MSF/RO |

| Al Khobar | Saudi Arabia (East Coast) | 811 | 1989-2002 | MSF |

| Al Jubail | Saudi Arabia (East Coast) | 1,012 | 1989-2002 | MSF/RO |

| Barcelona | Spain | 200 | RO | |

| Torrevieja | Spain | 240 | RO | |

| Taweelah | United Arab Emirates | 385 | RO | |

| Umm Al Nar | United Arab Emirates | 394 | 2007 | MSF |

| Fujairah | United Arab Emirates | 492 | 2010 | RO |

| Carlsbad | United States (California) | 190 | 2016 | RO |

RO: Reverse Osmosis; MSF: Multi-Stage Flash, This table will be updated from time to time as more information becomes available about desalination plants around the world.

Where can I read more about water?

You may find two books an informative read. Canadian author Marq de Villiers won the Governor General award for Non-Fiction for his book Water: The Fate of Our Most Precious Resource (McClelland, 2003). Also, Prof. David Sedlak's Water 4.0: The Past, Present, and Future of the World's Most Vital Resource (Yale University Press, 2015) is an up-to-date must-read on the topic.

References:

- R. Clayton: Desalination for Water Supply, Foundation for Water Research, London, May 2011.

- WateReuse Association: Seawater Desalination Costs , January 2012.

- Megascale Desalination, MIT Technology Review,

- International Desalination Association

- Justin Gillis: For Drinking Water in Drought, California Looks Warily to Sea, New York Times, April 11, 2015.

- Adam Nagourney, Jack Healy and Nelson D. Schwartz: California Drought Tests History of Endless Growth, New York Times, April 4, 2015.

- Matt Weiser: Could desalination solve California's water problem?, The Sacramento Bee, October 18, 2014.

- Isabel Kershner: Aided by the Sea, Israel Overcomes an Old Foe: Drought, New York Times, May 29, 2015.

- Tina Casey: World's Largest Solar Powered, Jellyfish-Fightin' Desalination Plant to Be Built in Saudi Arabia, Clean Technica, January 22, 2015

- Ronan K. McGovern and John H. Lienhard V: On the potential of forward osmosis to energetically outperform reverse osmosis desalination, Journal of Membrane Science 469, November 2014, 245-250.