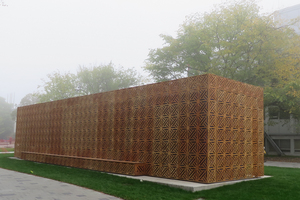

UBC is letting off steam—by converting its entire campus from steam to hot-water heating. Along the way UBC will reduce its environmental footprint significantly because hot-water heating is more energy-efficient. The container that is pictured on the right on a foggy October morning, UBC's Temporary Energy Center (TEC), plays a central role in this conversion. It is located on University Boulevard right in front of Henry Angus (I can see it from my office window), and architecture students designed the beautiful latticework that hides the metal container that houses two steam-to-water heat exchangers.

UBC's conversion from steam to hot water is supported by a strong business case as well as a strong environmental case. The conversion is part of a much larger plan for a new Academic District Energy System (ADES) that includes a biomass power plant (known as the Bioenergy Research and Demonstration Facility) and a new 60 Megawatt natural-gas powered Campus Energy Centre that is currently under construction and is expected to be completed by the end of 2015. At a cost of $88.3 million, the ADES project will replace 14 kilometers of UBC's steam lines and reduce UBC's energy use (and thus carbon dioxide emissions) by more than 20%. The project will eventualy pay for itself. It is expected to generate $5.5 million in annual savings from reduced energy use.

So why does the TEC pictured above play a pivotal role? The sooner the old steam pipes can be replaced by hot-water pipes, the sooner energy can

be saved. Eventually, the new Campus Energy Center will provide the hot

water directly, but until then UBC's old power plant will generate steam.

Using hot-water pipes boosts efficiency because

they are much better insulated and have fewer heat losses.

They are also shorter

because steam pipes need more expansion joints than hot-water pipes.

Expansion joints are U-shaped pipe diversions that help pipes expand

and shrink as temperatures change inside the pipe. Without them the pipes

would break. Because hot water has a lower temperature than steam, fewer

expansion joints are needed.

Expansion joints are U-shaped pipe diversions that help pipes expand

and shrink as temperatures change inside the pipe. Without them the pipes

would break. Because hot water has a lower temperature than steam, fewer

expansion joints are needed.

Inside the TEC are pumps (pictured on the left) that power two heat exchangers. Most of the time only pump runs (alternating every few days), and only in the depth of winter both pumps run. The heat exchangers transfer heat from UBC's old power plant to the hot-water pipes that circulate hot water around the campus. The heat exchanger brings the water to temperatures that can range from 60°C to 115°C—warmer in the winter and cooler in the summer. During October, the supply temperatures are about 80°C. After heating the buildings on campus, the returning water is about 20°C cooler. The steam from the power plants arrives at a temperature of about 190°C and a pressure of 550 kPa (80 psi). Each heat exchanger can manage a flow of 3,000 liters per minute, and can transfer up to 7.5 MW of energy. There are also two smaller heat exchangers in the TEC that help make the system more efficient internally.

Heat exchangers work by bringing a hot medium and a cold medium in close contact and transferring the heat from one to the other. To make this work efficiently, a heat exchanger provides a large surface for transfering this heat, typically through a multitude of small pipes running through a larger pipe.

UBC's experimental biomass power plant also plays a role in delivering heat. The steam generated at this plant is routed to heat exchangers in the nearby University Services Building. The biomass plant contributes about a quarter of UBC's heatig needs. Because it burns wood chips, the plant is effectively carbon neutral as its carbon dioxide emissions are absorbed by growing trees. The biomass plant can also be operated in an experimental thermal-and-electricity mode, but there are challenges in making this work just right. As a consequence, the two General Electric Jenbacher engines will be operated by natural gas in the future, delivering up to 1.5 Megawatts of electricity (about 7.5% of the campus's total demand).

The concept of district energy makes a lot of sense for a high-density academic campus with many institutional buildings. It also works well in high-density urban areas, and thus it is more common in some European cities than in the typical low-density cities in North America.

The Temporary Energy Centre on University Boulevard will remain temporary. When the new Campus Energy Centre takes over, the old powerhouse steam plant will be decomissioned. At that point, the TEC will become obsolete as well. As the equipment in the TEC will still be quite new and valuable, it can be resold. It is expected that a fair amount of the original $1.15 million construction cost can be recovered.

![[Sauder School of Business]](logo-ubc-sauder-2016.png)

![[The University of British Columbia]](logo-ubc-2016.png)