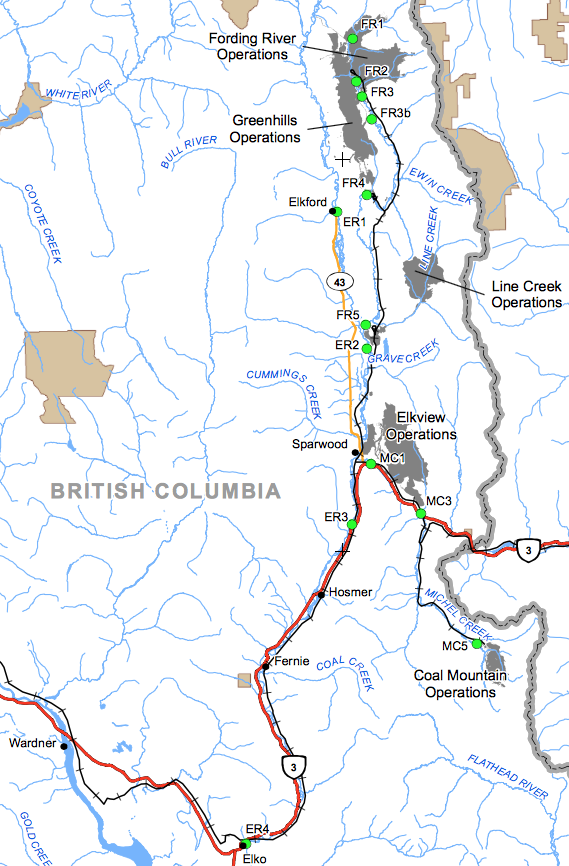

Over the last years, concerns have been raised about high levels of selenium in the Elk River and Lake Koocanusa. The Elk Valley is located in the East Kootenay region in the southeast corner of British Columbia, almost at the border to Alberta. The Fording River is a tributary to the Elk River, which flows south into Lake Koocanusa that spans across the border into the United States. The Elk Valley is home to five metallurgical coal mines operated by Teck; from north to south: Fording River, Greenhills, Line Creek, Elkview, and Coal Mountain. This Q+A explains some of the issues related to selenium and coal mining.

What is selenium?

Selenium is a naturally occurring element (chemical symbol: Se). Coal is a major geologic source of selenium. Natural processes distribute selenium and transform it into different species. In addition to its pure form, selenium is usually found in its oxydized forms selenate and selenite. Selenium species in water can exist in dissolved and suspended particulate form.

What are the adverse effects of selenium on the ecosystem and human health?

While selenium is an essential element of nutritional needs of animals and humans, it is only needed in a very small dosage. Dietary reference values for humans are 55-75 micrograms per day. Selenium deficiency can lead to Keshan disease and Kashin-Beck disease in humans. Nutritional requirements for fish, amphibians, and birds are less than 0.5 milligrams selenium per kilogram (mg Se/kg). Toxicity may occur in some species at concentrations above 5 mg Se/kg. At concentrations that exceed toxic thresholds, selenium is deleterious to fish: it is associated with embryonic deformities in fish eggs and reproductive failures that can even lead to population collapse. Selenium can also biomagnify through the food chain. Elevated concentrations of selenium have been found in cutthroat trout, frogs, and red-winged blackbirds.

What are the regulatory limits for selenium?

In the United States, the Environmental Protection Agency (EPA) regulates selenium levels under the Clean Water Act. It has set a recommended maximum level of 5 micrograms selenium per liter (μg/L). In Canada, aquatic ecosystems are protected under the federal Fisheries Act in cooperation with the provinces. The Canadian Council of Ministers of the Environment (CCME) has set Water Quality Guidelines, which for selenium are 1 μg/L in freshwater. In 2014, British Columbia updated its own guidelines. In deviation from the country-wide guidelines, British Columbia has set a higher guideline of 2 μg/L in freshwater and marine aquatic life, while setting an "alert concentration" of 1 μg/L. The standard for source drinking water is 10 μg/L, following a Health Canada recommendation.

In addition to national limits, there are also obligations jnder an international treaty between the United States and Canada. Concluded in 1909, the Boundary Waters Treaty mandates that shared waters cannot be polluted on one side of the border and cause harm on the other side of the border. Canada has an obligation to the United States to keep pollution out of the Elk River.

How does coal mining contribute to selenium pollution?

Open-pit and surface mining of coal produces large amounts of waste rock—also known as overburden. Runoff from this waste rock can release large amounts of selenium that eventually reaches rivers and lakes. Selenium tends to concentrate with the sulfur-containing minerals. Once exposed to air, it tends to oxidize into selenite or selenate. When selenite and selenate are exposed to water, these species of selenium will leach out from the rock. Therefore, selenium control strategies focus on (a) preventing oxidization of selenium, and (b) preventing water contact with leachable forms of selenium.

What is the level of selenium pollution in the Elk Valley?

A research study authored by Richard Hauer and Erin Sexton of the Flathead Lake Biological Station at the University of Montana reported that concentrations of selenium in the Elk River below the Teck mines “exceeded both the B.C. guidelines and the U.S. EPA water quality standard.” They found that concentrations were typically seven to 10 times above naturally occurring levels. At five measurement stations downstream from the coal mines, the selenium concentrations reached 7-10 μg/L. Other reports, including Teck's own, have pointed to selenium levels that have reached 11-57 μg/L at the upper Fording River. A recent report for Environment Canada pointed to measured concentrations between 5 and 113 μg/L in the Upper Fording River.

In addition to the elevated levels of selenium, nitrates and sulphates also showed abnormally high levels.

What technologies are available to mitigate selenium pollution?

Treatment of relatively dilute contaminants (less than 25 mg/L) is considered technically challenging. What adds to the complexity for selenium is that it occurs in several chemical species, some of which are water-soluble and others in particulate form. Treatment options are influenced by the characteristics of the water such as electrical conductivity (ionic strength), alkalinity (pH level), scale formation and total suspended solids. The treatment options can be sorted into three broad categories.

are in the microgram per litre range- Mechanical Treatment involves pressure-driven membrane filtration, where the filter provides a physical barrier for the selenium. Depending on the particle size, membrane systems can be classified as microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. As the particle size decreases, pressure needs to be increased, and this results in higher energy costs. Membranes usually consist of synthetic organic polymers. Reverse osmosis has been shown to be effective for removing selenium at various mining locations. A challenge is that the membranes may get fouled when calcium, magnesium, sulfate, silica, and other suspended solids. Selenium is captured in concentrated form and needs to be treated further through evaporation or drying. This technology has overall recovery rates of 70-90%.

- Chemical Treatment can remove selenium from water through physical adsorption, or oxidation/reduction. Adsorption materials can capture selenium, and the resulting sludge needs to be dewatered and disposed of in suitable offsite facilities. Adsorption technologies are widely implemented at full scale, but does not work for reducing selenium levels below 5 μg/L. Zero valent iron (ZVI) technology can also be used to reduce the oxidized forms of selenium, selenate and selenite. The ZVI media will eventually need to be removed and replaced, and the frequence of this depends on the selenium concentration. ZVI has not been used in full-scale operations yet.

- Biological Treatment make use of microorganisms. This requires the design of bioreactors that remove selenium through biological oxidation and reduction processes. Because of the biological nature of the process, it is sensitive to environmental conditions. Temperatures of less than 15°C result in substantial reduction of biological processes, and ideal temperatures are around 30°C. Maintaining ideal temperature conditions can be a challenge in colder climates. Also, water with high salinity or low levels of nitrate can pose challenges. The bacteria also need sufficient "fuel" (carbon), and this may need to be added in various forms. Bioreactors come in two different types: attached growth and suspended growth. Attached growth systems, which contain a layer of microorganisms—a biofilm—on a surface such as sand. The microorganisms stay attached to the media, but as the biofilm thickens, parts of it will detach and need to be captured. Two popular types of attached growth systems are the ABMet technology, and fluidized bed reactors. In suspended growth systems, the microorganisms are mixed into the water as "activated sludge." Clarifying tanks capture and recycle the activated sludge as it passes through the system. Suspended growth systems are more suitable for highly-polluted water, whereas attached growth systems are more suitable for lightly-polluted water.

What have we learned from the experience of Teck with its new water treatment plant at the Line Creek mine in the Elk Valley?

Some groups have called for an outright ban of coal mining in the East Kootenay region. However, the waste rock that has already been produced will continue to release selenium into the environment for decades. Production bans would not stop the selenium problem, but instead would discourage the producers from investing into water treatment facilities.

Teck is building a $100 million water treatment plant at the Line Creek site and is planning to build more. The company has earmarked $600 million over five years to improve water treatment at all of its mines. The full-scale water treatment plant at Line Creek uses a biological treatment process. Contaminated water collected from the river will pass through bioreactor tanks that contain an adsorbent, sand, which organic matter attaches itself to and grows, and in turn lets selenium attach itself to the organic matter. A carbon source is added, which combines with the organic matter and reduces selenium to an insoluble form that can be separated and removed from the water. The cleaned water is discharged after being oxygenated, while sand filters remove any remaining solids. Solids are thickened, collected, and trucked to a permanent fully-contained storage facility. The facility is projected to handle 7,500 cubic meters of wastewater per day. It went into operation in July 2014. The treatment facility will operate at a cost of $5 million per year.

Technically, the Line Creek water treatment plant makes use of fluidized bed reactor (FBR) technology. Selenium-contaminated water is forced through sand at sufficiently high velocities to "fluidize" the media. This promotes attached growth under anaerobic (oxygen-less) conditions. The FBR is seeded with bacteria that are suited for nitrate and selenium removal. Because the FBR requires anaerobic conditions, the treated water needs to be re-aerated (oxygenated).

In October 2014 it was widely reported that the treatment facility was shut down as a precautionary measure after dead fish had been found near the plant. The start-up of the facility requires significant lead time because the bioreactors need to build up sufficient biomass to operate correctly. A restart of the facility is expected during the spring of 2015. Teck is working towards understanding the problems with the new water treatment technology.

Teck's new selenium water treatment plant at the Line Creek mine.

Teck's financial commitment to building the water treatment plants is laudable. The company's experience with biological treatment will also be of interest to other companies that are facing similar environmental challenges.

Further readings and resources:

- BC Ministry of EnvironmentAmbient Water Quality Guidelines for Selenium, August 2001, and Ambient Water Quality Guidelines for Selenium, Technical Report Update, April 2014

- Mark Hume: Teck Coal facing serious water pollution in Elk Valley and ‘Elk River is being poisoned’ by coal mining, study finds, The Globe and Mail, March 21, 2013.

- Mark Hume: B.C. orders Teck Coal to submit selenium plan, The Globe and Mail, April 15, 2013.

- Mark Hume: B.C. prepared to risk water quality on Elk Valley coal mine, The Globe and Mail, November 24, 2013.

- Mark Hume: Coal mining, selenium, and the costs of toxic pollutants, The Globe and Mail, January 20, 2014.

- Mark Hume: Elk Valley watershed: Why has this unfolding disaster been ignored?, The Globe and Mail, October 19, 2014.

- Mark Hume: Teck Resources water-treatment plant shut after dead fish found, The Globe and Mail, October 28, 2014.

- Teck: Valley-wide Selenium Management Action Plan, February 2013.

- Tom Sandy and Cindy DiSante: Review of Available Technologies for the Removal of Selenium from Water, CH2MHILL, June 2010. Report prepared for the North American Metals Council.

- F. Richard Hauer and Erin K. Sexton: Transboundary Flathead River: Water Quality and Aquatic Life Use, Flathead Lake Biological Station, The University of Montana, Polson MT, March 4, 2013.

- A. Dennis Lemly: Review of Environment Canada's Teck Coal Environmental Assessment and Evaluation of Selenium Toxicology Tests on Westslope Cutthroat Trout in the Elk and Fording Rivers in Southeast British Columbia, Expert Report, September 25, 2014.

![[Sauder School of Business]](logo-ubc-sauder-2016.png)

![[The University of British Columbia]](logo-ubc-2016.png)